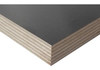

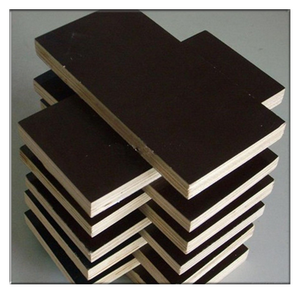

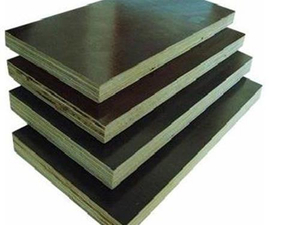

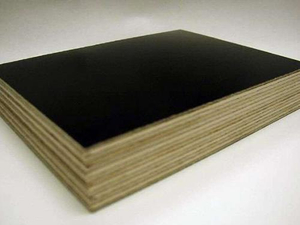

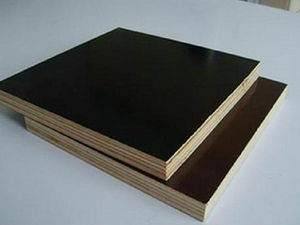

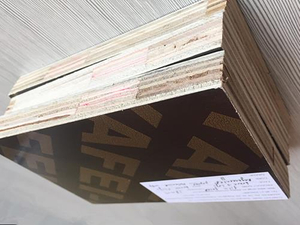

Construction Plywood was the first type of engineered wood to be invented. It is made from thin sheets of wood veneer, called ply or veneers. These are stacked together with the grain direction of the ply differing from its neighbours’by 90º (cross banding).

Wood species

Birch/poplar/eucalyptus

Panel size

1220 x 2440/ 1250 x 2500 mm

* The possibility to manufacture sizes and thicknesses according to the customer's requirements.

Thickness

From 12mm up to 40 mm

Bonding classes

Plywood is glued with phenolic resin adhesive that meets the following standards:

BS 1203 / H4 (WBP)

DIN 68705 part 3 / type BFU 100

EN 314 / 3rd class

Formaldehyde emission level shall not exceed 0.2 mg HCHO/m2h, which meets the standard E1

* We can supply you film faced plywood with MUF wbp glue according to your requirement.

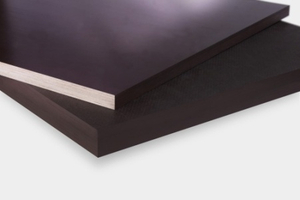

Overlay

Phenol film, dark brown or black, weight 120 g/m². Different colors and film weights are available on request. Wear resistance of the surface demands on the film weight and can be presented as the following:

120 g/m² - 400 rotations according to Taber test (EN 438-2)

220 g/m² - 750 rotations according to Taber test (EN 438-2)

Other parameters

Formaldehyde emission: E1

Moisture content: max 12 %

Application

Shuttering systems, the production of the concrete prefabricates

Automotive industry (containers and trailers sidings)

Boatbuilding

Decorative packaging and boxes

Playgrounds

Sport equipment

Toys

"Flight Cases" type cases